Tech Report

Designing high speed dispersers for large-scale mixing processes

Technology Brief

In addition to maintaining basic design parameters, high speed dispersers can be specially engineered to support high volume production requirements.

Basic design parameters

The high speed disperser (HSD) is a basic mixing device used by many paint, ink, chemical, plastic and adhesive manufacturers. Typically equipped with a saw-tooth disc-style blade, the HSD creates vigorous flow conditions ideal for mixing powders into a liquid batch. Mixing performance is optimized by following a few basic design guidelines including:

- Normal operating viscosity range: 1,000 - 25,000 cP and up to 50,000 cP max

- Motor specification: 1HP for every 10 gallons of product

- Disperser blade diameter: approximately 1/3 of vessel diameter

- Disperser blade tip speed: ~5,000 ft/min [Tip speed (ft/min) = blade diameter (ft) x 3.1415 x shaft speed (rpm)]

- Disperser blade location: min 0.5 blade diameter off the vessel bottom

- Full holding capacity of mix vessel: about 130% of batch size

Challenges of large-scale mixing

As batch volumes become larger, the challenges of maintaining these design parameters become apparent. Because blade diameter is essentially determined by vessel size, very large high speed dispersers eventually require horsepowers that are impractical.

Some process engineers solve this problem by installing a smaller diameter blade that runs at higher shaft speeds to maintain the desired 4800-5200 ft/min dispersion tip speed. However, this has the danger of approaching critical speed and increases the risk of premature equipment failure. A safer option is to utilize supplemental agitation, such as a slow speed propeller or an anchor agitator, to help "feed" product to the disperser blade, improve bulk flow within the vessel, and eliminate "dead zones".

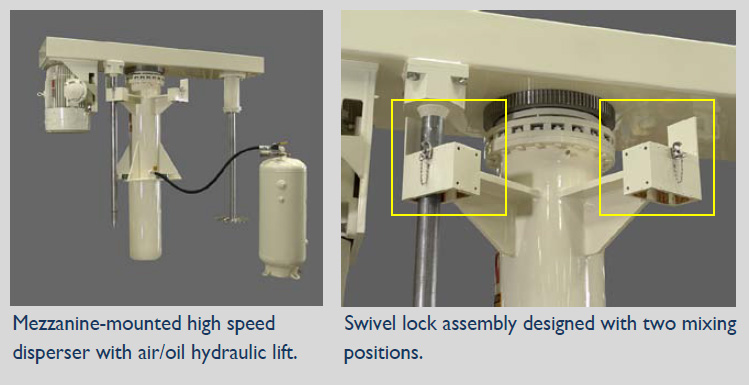

In cases where a multi-agitator set-up is not convenient, one possible solution is to cut down batch size and focus on ways to accelerate mixing and changeover to achieve the target production rate. For instance, a high speed disperser equipped with a swivel system can significantly reduce changeover time. Typical tank-mounted dispersers cannot start the next batch until all contents of the previous run are emptied and fresh raw materials are charged to the same vessel. In comparison, a mixer that can be raised hydraulically out of one vessel, rotated and lowered into another vessel allows for a more nimble and cost-efficient method of production.

Sample Application: Refractory Coatings

The above Ross High Speed Disperser with swivel system is being used to mix refractory coatings, binder solutions, adhesives and sealants.

Safety limit switches prevent operation of the disperser if a mix vessel is not in position. In addition, a height limit switch allows the HSD to operate within an acceptable operating range – from the fully down position to a safe raised height. This range is required in most applications to allow the operator to adjust the blade position during mixing to eliminate any potential stratification within the batch. It is also useful for handling low liquid volumes during the initial stages of mixing prior to addition of powders and other components.