Tech Report

Design considerations for tumble blenders

Technology Brief

This bulletin discusses some factors to consider when selecting and specifying tumble blenders.

Basics and benefits of tumble blending

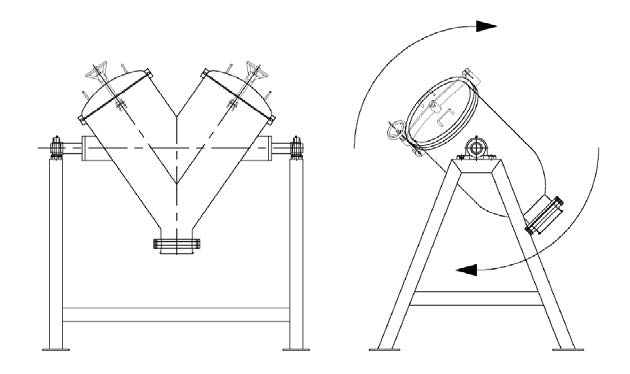

A tumble blender is a rotating device that comes in a variety of geometries, the most common being the V-shaped or double-cone configurations. The vessel is partially loaded with product and rotated at operating speeds in the range of 5 to 25 revolutions per minute. Diffusion is the main mechanism for mixing: batch materials cascade down, distributing particles over a freshly exposed surface as the vessel rotates on a horizontal axis.

In a V-shaped blender, the batch is continuously being split and recombined. In order to take advantage of this mixing and flow pattern, raw materials are generally loaded to the vessel in layers rather than side by side.

Tumble blending is very low-impact and appropriate for processing abrasive solids. It is also commonly used in making precise blends containing trace components (<1%) or ingredients that are vastly dissimilar in size and density.

The geometry of the V-shaped and double-cone vessels allows complete discharge of the blended material. Both designs however require a large footprint to accommodate the mixer base, as well as ample overhead space for the vessel to rotate. In certain installations, this type of equipment is operated from within a dedicated room to ensure safety.

Some design considerations

- Ease of cleaning. The tumble blender is easily accessible for cleaning. Smoother finishes on the wetted surfaces improve cleanability.

- Reduction of lumps. The gentle blending action of the rotating vessel is not suitable for breaking down tough lumps in the batch. A high speed intensifier bar is required for applications that need sufficient shear to reduce the size of agglomerates. This intensifier bar is installed along the blender`s axis of rotation.

- Solid/liquid mixing. Tumble blenders can be used for mixing low-viscosity, slurry-type applications where the liquids and solids are all added through the vessel cover. If the liquid phase is a minor ingredient in the blend, it can be continuously sprayed across the solids as the blender is rotating. To accomplish this, spray nozzles are installed on the high speed intensifier bar designed for liquid addition.

- Drying requirements. Drying applications often benefit from having a jacketed vessel that is also rated for vacuum. Vacuum drying is an excellent method for drying heat-sensitive products because it requires lower heat to drive off moisture or solvents compared to drying under atmospheric conditions.

- Controls. The most basic controls allow you to start, stop and jog the motor. However, a variable frequency drive is typically recommended as it allows soft start under full load conditions. It also enables adjustment of rotation speed so that the contents can slide or cascade to the lower portion of the rotating vessel at a controlled rate. If preferred, the blender can be programmed to shut off automatically after a certain number of revolutions.

Sample Application: Powdered Metals

A Ross Tumble Blender produces powdered metal blends for filter applications. This heavy-duty unit is designed to handle product densities up to 200 lbs/cu.ft.

In addition to discussing the above design considerations with your blender supplier, make sure to provide accurate bulk density data for all the formulations you are looking to process in the same tumble blender. This information is critical to selecting the correct model and properly sizing motor horsepower.