The Expert's Corner

Why Invest in Ross Syscon Controls?

March 19, 2019

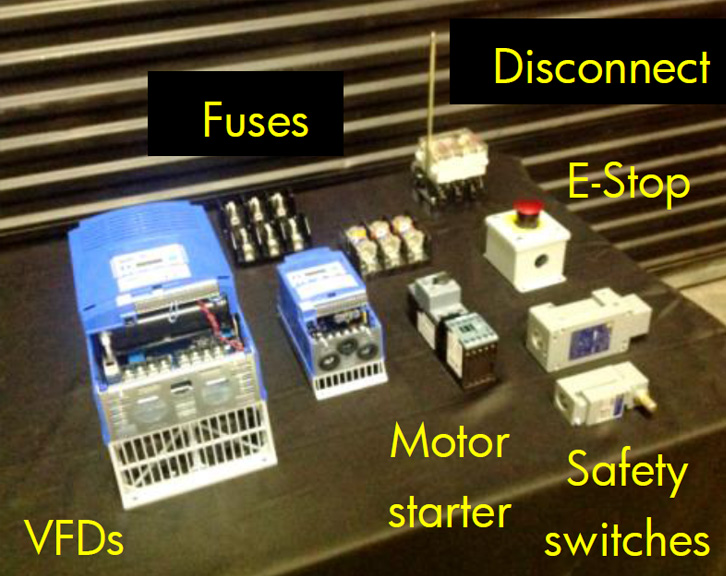

Let`s compare the benefits and issues associated with buying a loose Variable Frequency Drive (VFD) to control a Ross mixer vs. an integrated Ross SysCon Control Panel.

Loose VFD Loose VFD |

Ross SysCon Control Panel Ross SysCon Control Panel |

|---|---|

|

|

Sample Equipment: PowerMix Planetary Disperser

- 3 HP motor for the planetary stirrer

- 7.5 HP motor for the high speed disperser

Loose VFD Loose VFD |

Ross SysCon Control Panel Ross SysCon Control Panel |

|---|---|

|

|

Ross Systems and Controls is a full service machine and controls fabrication facility. We have extensive experience in designing and building control systems not only for Ross Mixers and Blenders but also other types of equipment and processes. All Ross SysCon products are tailored to the customers` exact requirements – from simple start/stop/speed commands to PLC-based recipe driven systems with supervisory control and data acquisition (SCADA) packages.