Tech Report

Benefits of batch ultra-high shear mixing and homogenization in the chemical industry

Technology Brief

Consider an ultra-high shear rotor/stator mixer for your process. Compared to other batch style mixers including high speed dispersers, traditional rotor/stator mixers and immersion mills, an ultrahigh shear mixer delivers more superior particle or droplet size reduction.

High speed rotor/stator mixers

Throughout the process industries, high speed mixers are commonly used for a number of objectives including powder wet-out and dispersion, solubilization, particle size reduction and homogenization. In particular, rotor/stator style mixers, also called high shear mixers, are considered to be one of the most versatile systems due to their ability to prepare fine emulsions as well. Available in batch and inline configurations, these mixers are comprised of a rotor that turns at high speed within a stationary stator. As the blades rotate, materials are continuously drawn into one end of the mixing head and expelled at high velocity through the openings of the stator. The resulting hydraulic shear promotes fast mixing, disintegrates solid agglomerates and accelerates emulsification.

The main drawback of rotor/stator mixers is insufficient product turnover at elevated viscosities. As the batch material approaches 20,000cP, a conventional rotor/stator system may start to exhibit poor product flow within the vessel, often resulting in localized heating of materials near the high shear zone. In addition, the mixing intensity generated by this type of device is sometimes not adequate for producing extremely fine particle or droplet size distributions.

Delta rotor/stator technology

To address the abovementioned limitations, Ross developed the PreMax, a top-entering batch mixer with Delta ultra-high shear rotor/stator technology (US Patent No. 6,000,840). The Delta rotor is specially contoured for high pumping capacity and shear intensity. Product is drawn from above and below the rotor and expelled radially through the stator slots at high velocity. This generates upper and lower vortices allowing for extremely efficient powder additions and rapid turnover rates. Very fine droplet sizes are achieved while solids are quickly wetted out instead of floating on the liquid surface.

The PreMax is typically used as a stand-alone unit and does not require supplemental agitation for products up to 50,000 cP. For higher viscosity products, it is supplied in a multi-shaft mixer arrangement equipped with an anchor agitator.

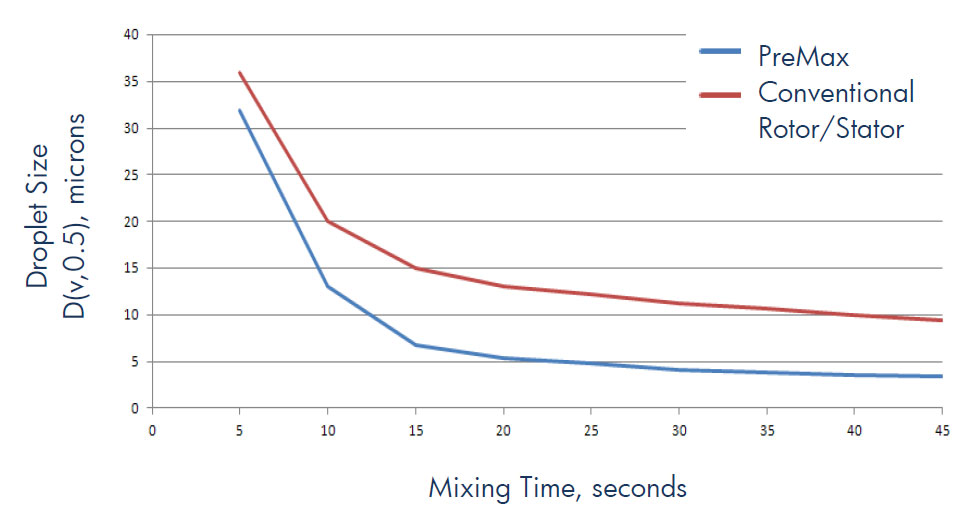

Compared to other batch style mixers including high speed dispersers, traditional rotor/stator mixers and immersion mills, the PreMax delivers more superior particle or droplet size reduction. The graph below shows average droplet sizes of an oil-in-water emulsion prepared on a conventional high shear rotor/stator mixer and on the PreMax ultra-high shear mixer.

Ross PreMax Batch Ultra-High Shear Mixer

Sample Applications:

Numerous PreMax Ultra-High Shear Mixers are installed in facilities producing chemical solutions, ceramic slurries, polymer and pigment dispersions. The end products vary from advanced coatings to cosmetics, inks, adhesives, sealants, and composites.

In some of these applications, the PreMax delivers results comparable to one or two passes through a media mill. This reduces the number of mill passes required to achieve the final particle size, and in some cases, eliminates milling entirely.