Tech Report

Hybrid planetary mixers produce high viscosity mixtures with ultra-fine dispersion quality.

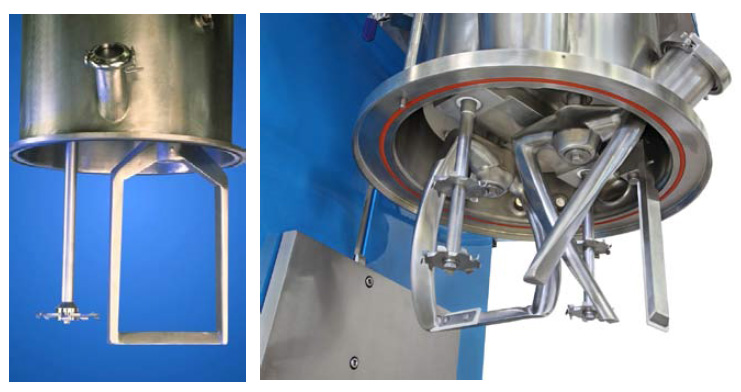

Planetary mixers are equipped with two or more blades that rotate on their own axes while revolving around the mix vessel. Compared to traditional planetary mixers with two identical stirrers, hybrid planetary mixers feature at least one high speed, high shear blade. Left: Rectangular stirrer and high speed disperser. Right: Two helical stirrers, two dual-blade high speed dispersers and a sidewall scraper arm.

Technology Brief

Hybrid planetary mixers are utilized for creating fine dispersions in viscous mixtures, typically within the viscosity range of 100,000 to 2 million cP. Intense mixing is applied to the product by constantly advancing a high speed disperser and a low speed stirrer into the batch. Solids are quickly incorporated into the viscous bulk material and agglomerates are dispersed regardless of product flow characteristics.Designs for multiple planetary stirrers and disperser blades are available for more demanding applications.

Mixer design criteria: viscosity and degree of dispersion

The ideal mixer design for any application is determined on the basis of many criteria but the most important are viscosity and degree of dispersion. A high shear rotor/stator device, for example, is commonly recommended for flowable mixtures that require a fine particle size distribution; on the other side of the spectrum, a double planetary mixer is typically used to accomplish thorough blending of components into a high viscosity vehicle. For everything else in between, a myriad of mixer configurations are available for selection.

Mixing of moderate to high viscosity products

In processing moderate to high viscosity products, single shaft mixers such as propellers, sawtooth blades and rotor/stators are incapable of producing adequate material turnover. For this reason, these devices are often used in combination with a low speed sweep agitator. The agitator helps to exchange materials from different parts of the vessel, essentially "feeding" the high speed device with product that would otherwise not flow towards it.

As viscosity rises, however, even a multi-shaft mixer arrangement will eventually fail to produce sufficient flow. For example, the sweep agitator may simply carve a path through the viscous batch as agitation close to the axis of rotation becomes more and more limited.

Hybrid planetary mixers

When dealing with viscous applications in the range of 100,000 to 2 million cP, creating a fine dispersion is more efficiently done on a hybrid planetary mixer. The classic design consists of a planetary stirrer and a high speed disperser blade that revolve on their own axes while orbiting the vessel on a common axis (click here to see video). By constantly advancing the agitators into the batch, both blades contact fresh product all the time. This mechanism applies intense mixing action and uniform heat distribution.

Shear levels and flow patterns are easily fine-tuned because the agitators are individually-controlled. More demanding applications benefit from multiple planetary stirrers and disperser blades. Solids are quickly incorporated into the viscous bulk material and stubborn agglomerates are dispersed regardless of product flow characteristics.

Products that undergo a viscosity peak mid-processing, even if the final viscosity is relatively manageable in a multi-shaft mixer, are also ideal candidates for processing in a hybrid planetary mixer. So are applications that are batched in a double planetary mixer, let down, and further mixed using a high speed device to achieve the desired level of dispersion.

In reality, many of today`s mixing technologies overlap in use and function. By comparing capital costs and measuring efficiencies through simulation trials, one can determine the best solution for a particular mixing requirement.

Ross Hybrid Planetary Mixers: Sample Configurations

Rectangular Planetary Stirrer and High Speed Shaft with Disperser Blade

Rectangular Planetary Stirrer and High Speed Shaft with Two (2) Disperser Blades

Rectangular Planetary Stirrer, High Speed Shaft with Two (2) Chopper Blades, and Sidewall Scraper Arm

High Viscosity "HV" Planetary Stirrer, High Speed Shaft with Disperser Blade, and Sidewall Scraper Arm

Two (2) High Viscosity "HV" Planetary Stirrers, Two (2) High Speed Shafts with Two (2) Disperser Blades each, and Sidewall Scraper Arm

Sample Application: Electrode Paste

Viscous battery pastes with ultra-fine dispersion quality are being made on this Ross Model PDDM-4 Planetary Dual Disperser.

This unit is equipped with two helical planetary stirrers, one of which includes a bottom scraper. Two saw-tooth blades are installed on each high speed shaft. A scraper arm removes material from the vessel wall to ensure superior heat transfer during the mixing process.