Tech Report

Mixer options for pureeing and liquefying solids

Technology Brief

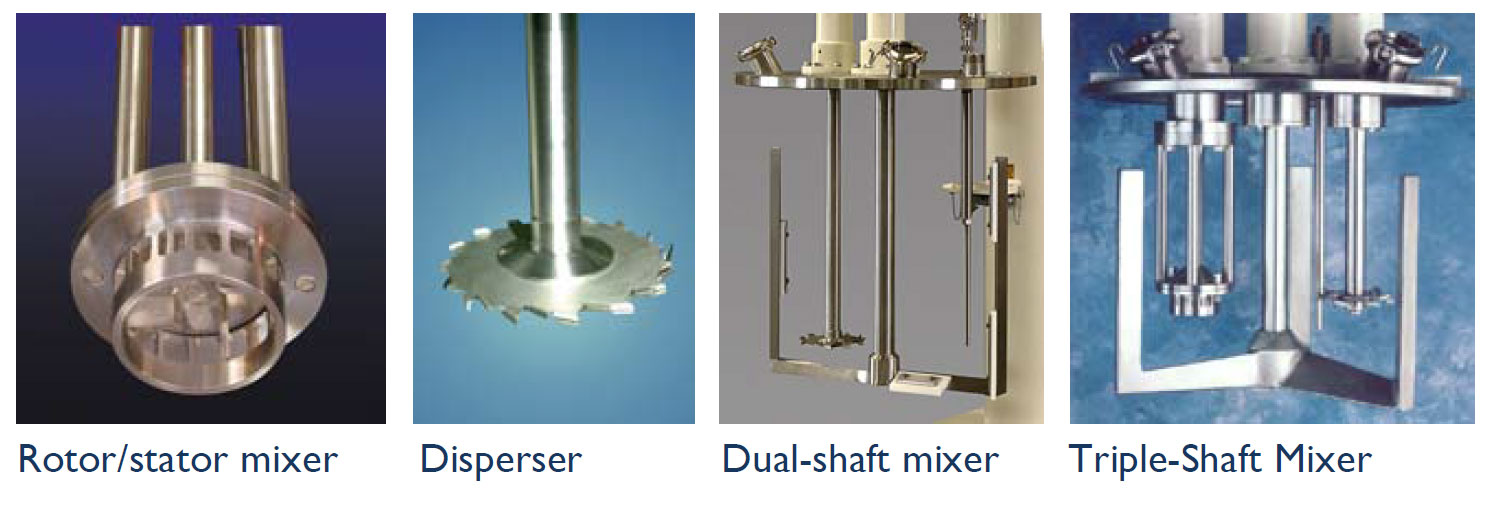

A variety of mixers are suitable for pureeing requirements - from single-shaft rotor/stator mixers and high speed dispersers to multi-agitator equipment for higher viscosity formulations, and even ultra-high shear mixers which are used to achieve a high level of smoothness and consistency in some products.

Pureeing and liquefying solids

Pureeing and liquefying solids are classic mixing requirements throughout the food industry. Typical solids include fruits, vegetable and meats. End products range from soups and condiments, to flavorings and beverages.Mixer selection is generally dictated by viscosity and the characteristics of the solid component(s). The starting shape, size and hardness of the solids, the maximum viscosity reached by the mixture during processing, the final viscosity of the end product (if different from maximum viscosity) and the desired level of smoothness are all important considerations.

Single-shaft mixers

Conventional single-shaft mixers such as propellers and turbines are incapable of pureeing solids due to their relatively low speed range. Saw-tooth high speed dispersers and high shear rotor/stator mixers are used instead.

The high speed disperser features an open-style disc blade with sharp edges which can cut through pieces of soft solids. Running at tip speeds of around 5,000 ft/min, it generates a vortex into which solids can be added for quick incorporation into the batch. Alternatively, a batch may not need any starting liquid as long as the solids to be pureed occupy a sufficient volume, are relatively soft, and contain a high percentage of water. Dispersers are typically used in pureed applications up to around 50,000 cP in viscosity.

In comparison, a high shear rotor/stator mixer typically features a four-blade rotor running at tip speeds in the range of 3,000-4,000 ft/min within a close tolerance fixed stator. This type of device requires fluid in the batch at all times. It creates mechanical and hydraulic shear by continuously drawing product components into the rotor and expelling them radially through the openings in the stator. Because of the restriction provided by the stator, this mixer is limited on the size of solids that it can handle but offers greater shear than an open-disc saw-tooth disperser blade. For the same reason, its viscosity limit is lower - around 10,000 to 20,000 cP. The rotor/stator mixer is available in both batch and inline (continuous) designs.

Multi-agitator mixers

For moderate to high viscosity formulations, the disperser and/or rotor/stator mixer are used in combination with a low speed anchor agitator. The anchor agitator helps to exchange materials from different parts of the vessel, essentially "feeding" the high speed device(s) with product that would otherwise not flow towards it. With this configuration, a multi-agitator mixer can handle recipes that are several hundred thousand centipoise.

One advantage to having both a disperser and a rotor/stator in one mixer is that the disperser can be used to puree large solids at the start of the cycle and as the liquid portion of the batch increases, the rotor/stator can be turned on to eliminate lumps and improve homogeneity of the mixture. An inline rotor/stator may be used for this purpose as well and offers the added benefit of functioning like a pump for transporting the finished puree to downstream operations.

Preparing extra smooth purees

After processing in multi-shaft mixer, the puree may be fed into an inline ultra-high shear mixer to increase smoothness. Certain vegetables and fruits have hard skins or seeds that are difficult to disintegrate and can render a grainy quality to the mixture. In many cases, running the product through a Ross Ultra-High Shear Mixer (tip speed: 11,000 ft/min) breaks down these hard pieces and achieves a visibly smoother texture.

Sample Application: Sauces and Dressings

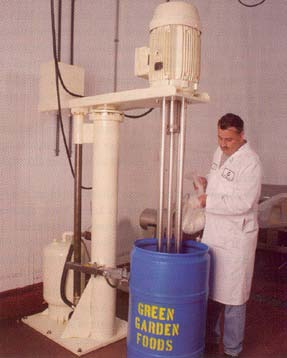

Green Garden Foods acquired a 30HP Ross Batch High Shear Mixer when they received a contract to make authentic African hot sauce.

On their high-speed, high-volume line, the rotor/stator provides the intense shear necessary to puree solid ingredients quickly.

Eventually, due in large part to the mixer`s flexibility, cost-efficiency and easy maintenance, the company expanded their capabilities and took on a whole spectrum of new products. Salsas, Asian sauces, sandwich spreads and various dressingsare now also being made on the Ross mixer.