Tech Report

Move your media mill process to an ultra-high shear mixer

Technology Brief

Specially designed rotor/stator mixers achieve ultra-high shear conditions which often result in extremely fine dispersions of pigments and other raw materials. More than just an ordinary `pre-mixer`, an ultra-high shear rotor/stator device can produce results comparable to one or two passes through a media mill.

Traditional method of pigment dispersion

Most modern pigment-based inks and coatings are still produced via the traditional two-stage process. First, the pigment is wetted-out to produce a dispersion within an appropriate mobile phase. Preparation of the "pre-mix" is commonly carried out using propellers, turbine agitators or saw-tooth dispersers mounted in open vessels. The rough pre-mix is then milled to reduce particle size through a process of agglomerate break-up and attrition. The milling step typically accounts for most of the operating costs and is the most time-consuming part of the process. Media mills are also notoriously difficult to clean.

One-stage processing in an ultra-high shear mixer

The capabilities of traditional pre-mixers are generally limited to the simple wetting out of powders prior to milling. A mixer that can wet out pigments and disperse agglomerates to the desired final grind offers significant improvements to a normally slow and operator-intensive process.

Ultra-high shear mixers in the form of specially designed rotor/stators are the newest answer to this issue. In certain applications, ultra-high shear mixers enable one-stage processing by combining the pre-mixing and milling operation in a single tank. This accelerates the entire cycle, eliminates transfers steps, and simplifies clean-up. In cases where ultra-high shear mixing does not necessarily eliminate milling but reduces the number of mill passes, the resulting two-stage process still offers substantial benefits in terms of improved throughput and maximized utilization of the milling equipment.

Conventional rotor/stator mixers

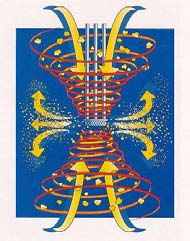

Many users have considered the use of rotor/stator high shear mixing devices for the pre-mixing portion of their pigment dispersion processes. These mixers consist of a high speed rotor running at close clearances to a fixed stator. Tip speeds between 3,000 to 4,000 ft/min are typical. This configuration creates intense mechanical and hydraulic shear by continuously drawing product components up into the open end of the rotor and expelling them radially through the openings in the stator.

The main drawback of these devices is insufficient flow. At elevated viscosities (>20,000cP), conventional rotor/stators may produce poor product flow within the vessel, resulting in localized heat concentrated near the high shear zone. In addition, the vortex it forms generally occurs below the mixing head and is not usually strong enough to pull solids down from the liquid surface as viscosity increases.

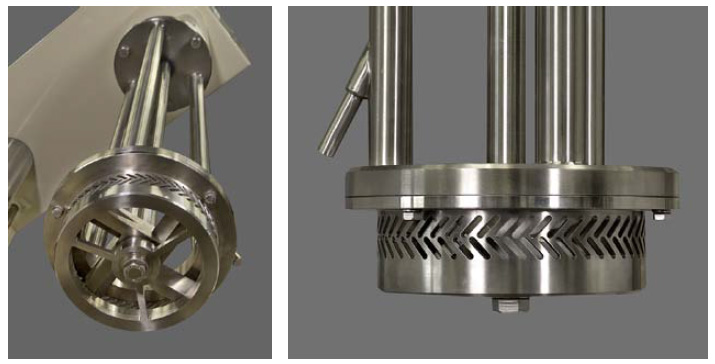

Delta rotor/stator technology

To address the above mentioned limitations, Ross developed the PreMax with Delta rotor/stator technology (US Patent No. 6,000,840) designed to run at higher tip speeds (5,000 ft/min) and create enhanced levels of shear. The PreMax also generates much greater flow within a batch, drawing materials from below the rotor and above it. Powders at the surface of the mobile phase are easily pulled right into the high shear zone, minimizing floating and dusting issues.

Pre-mixing with the PreMax can produce results comparable to one or two passes through a media mill. This reduces the number of mill passes required to achieve the final product particle size, and in some applications, eliminates milling entirely. Testing is available to confirm if your specific application can be finished in an ultra-high shear mixer.

Ross PreMax Batch Ultra-High Shear Mixer

Sample Application: UV-Curable Coating

A manufacturer of specialty coatings used to disperse titanium dioxide pigment at 40% loading into a blend of low-viscosity epoxy resin and liquid wetting agent in a batch tank equipped with a saw-tooth disperser. The resulting premix was then pumped to a ceramic bead mill and milled for four hours before being transferred to a downstream holding tank.

Simulation trials on a PreMax revealed that the milling step can be eliminated completely. Now, the UV-curable coating is batched and finished in a single tank. The Delta rotor/stator quickly wets out the pigment powders and, in 30 minutes, produces identical results as the previous milling process:an 8 Hegman or "off the gauge" dispersion.