Tech Report

Recommended Blending and Drying Equipment for Nylon Pellets

Application Summary

Nylon pellets are commonly blended with other plastics, coated with a powdered lubricant or mixed with concentrated pigments and other additives.

In certain cases, it is necessary to reduce the moisture content of the pellets to prevent defects in the finished product and process inconsistencies.Effective drying to an optimal level is critical because over drying can negatively impact the flow characteristics of nylon pellets.

The versatile Vertical Blender is a low-shear blending and drying equipment uniquely suited for accomplishing all of the above objectives.

Ross Vertical Blender/Dryers

Ross Vertical Blenders are well-proven equipment for blending nylon pellets with other polymers or solid additives virtually regardless of particle size and shape. These machines feature a slow-turning auger screw that orbits a conical vessel. As it turns, the screw gently lifts material upward and towards the center of the batch. Product from the top cascades back to the bottom while mixing with material being moved upward by the orbiting screw. This agitation mechanism is ideal for handling nylon resins because it is very thorough but does not damage the individual pellets. And unlike blenders that operate using a rotating vessel, the Vertical Blender is not sensitive to order of addition, positioning of raw materials nor fill level. At the end of the mixing cycle, the steep-angled vessel enables quick and complete discharge of the finished blend without segregation.

Drying to very low moisture levels is also easily achieved in a jacketed Vertical Blender designed for hot water, oil or steam recirculation. Coupled with vacuum conditions, the continuous turnover of materials within the heated vessel leads to fast and effective drying. A steady stream of dry air or inert gas may be introduced into the blender`s head space when removing large quantities of vapor to help accelerate drying time and prevent premature condensation within the vessel. In other agitated dryers such as ribbon/paddle blenders, rigid granules or pellets, depending on their size and shape, can bind against the agitator and overload the motor. TheVertical Blender`s auger screw is able to move more freely and constantly exchange product between different areas of the vessel without generating fines.

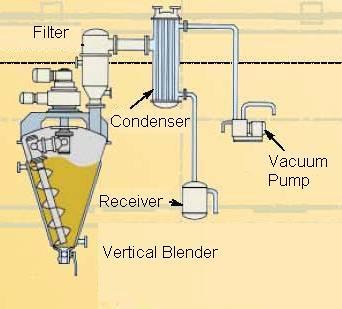

How a Vertical Blender/Dryer works:

Heat is applied to the jacketedvessel of the vertical blender.Once vacuum is established,the combination of lowabsolute pressure, gentle heatand slow agitation quicklyforces moisture from the bulkmaterial. Vapors generated inthe process pass through afilter and into a condenser. Areceiver collects thecondensed liquid forproper disposal or re-use,if applicable.

Other Applications ofRoss Vertical Blender/Dryers:

- Beverages

- Botanical Extraction

- Ceramic Powders

- Chemicals

- Detergents

- Fertilizers

- Fillers

- Foods

- Glass

- Herbicides

- Lubricants

- Microspheres

- Nutritional Supplements

- Pharmaceuticals

- Pigments

- Wood Fibers

Benefits of Ross Vertical Blender/Dryers

- Fully top-supported screw agitator. Without a bottom support bearing to get in the way, the blended batch is discharged quickly and completely. This design also allows the machine to be operated with very little maintenance.

- Many standard sizes. Standard models from 1 to 500-cu.ft. working capacity can be designed for a specific bulk density range.

- Smaller footprint compared to other types of blenders and dryers.

- Highly effective moisture removal. Ross Vertical Blender/Dryers are commonly used for vacuum drying materials to less than 0.10% moisture.

- Low energy consumption and fast drying rates.

- Customers can rely on Ross for customizations and auxiliary equipment, including internal pressure construction, pneumatically operated valves, custom ports and manways, inert gas injection nozzles, load cells, temperature probes, heating units, vacuum pumps and controls ranging from simple Variable Frequency Drives and operator stations to more sophisticated PLC`s and HMI`s.