Tech Report

Recommended Blending Equipment for Nutraceuticals

Application Summary

Nutraceuticals are supplied in many forms including tablets, capsules, drink mixes and powders.

Faced with an increasing demand for higher processing standards, nutraceutical companies are intensifying efforts on diligent equipment selection and good manufacturing practices. One of the key considerations is proper blending of the active ingredient(s), excipients, fillers, flavors, colors, lubricants and other additives to ensure consistent product quality, efficacy and purity.

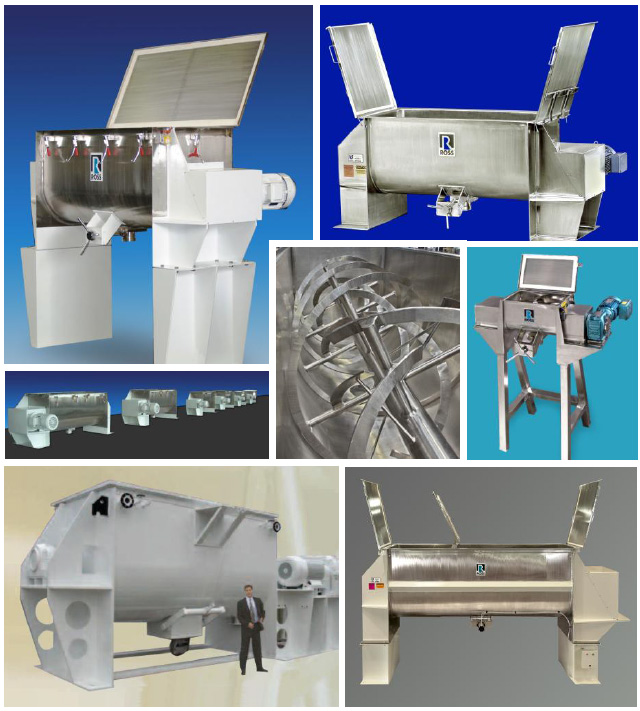

Ross Ribbon Blenders

Dry blending is an indispensable operation in the manufacture of multivitamins, sports supplements, herbal extracts, meal-replacements, green food powders and other nutraceutical products. Many supplement formulators and contract manufacturers accomplish this process on Ross Ribbon Blenders.Ingredients are loaded into a U-shaped trough and mixed by a horizontal agitator consisting of inner and outer helical ribbons. The position and precise pitch of each ribbon produce a well-balanced axial and radial flow pattern, promoting fast and thorough mixing. Maximum tip speeds are approximately300 ft/min but with variable speed control, the blending action can be fine tuned and optimized according to the characteristics of a particular recipe.

Other Sanitary Applications of Ross Ribbon Blenders:

- Baking Premixes

- Coffee Beans

- Dental Powders

- Drink Mixes

- Extruded Foods

- Flavorings

- Flours and Starches

- Food Additives

- Pharmaceuticals

- Canned Soups

- Sandwich Salads

- Seasonings

- Spices

- Sugars and Sweeteners

- Trail Mix Snacks

Benefits of Ross Ribbon Blenders:

- Flush valves, end wall scrapers and close tolerances between the outer ribbon and trough eliminate "dead zones" where product can collect. Interior stainless steel surfaces are also well-polished and each weld is "radiused" to prevent material buildup.

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike older belt-driven blenders which are noisy and prone to slippage, direct-driven Ribbon Blenders are more reliable and require less maintenance. These utilize compact gearmotors (one-piece motor reducers) and inverters, providing electronic speed control, soft-start capability and overload protection.

- Different duty models are available for accurate sizing according to bulk density. Standard capacities range from 1/2to 1,000 cu.ft.

- Ross Ribbon Blenders can be customized to include pneumatically operated covers, bag dump stations, special ports and discharge valves, interchangeable paddle agitator, liquid spray bar, load cells, vacuum design, high speed choppers, PLC recipe systems and many other options.