Tech Report

Recommended Drying Equipment For Plastic Resins

Technology Brief

Plastic resins attract moisture from ambient air. Water collects on the surface of theres in, and if the plastic ishygroscopic, water is retained within the polymer itself.

Drying is an important operation in plastics production because excessive moisture in the starting resin material can result in visual defects, lower strength and reduced performance of the finished part.

Ross Vertical Blender/Dryers

Vacuum-capable Vertical Blender/Dryers are proven equipment for drying plastic resins. These machines feature a slow-turning auger screw orbiting a conical vessel. As it turns, the screw gently lifts material upward and towards the center of the batch. At the same time, product from the top cascades back to the bottom while mixing with materials being moved upward by the orbiting screw. During the drying cycle, hot water, oil or steam is recirculated through the vessel jacket. Requiring relatively low temperatures to drive off moisture, vacuum drying is an excellent method for processing heat-sensitive plastics without fear of thermal degradation. The low energy consumption also minimizes operating cost.

Unlike in conventional ovens, tray dryers and hot air dryers where product is stationary, the layer of material contacting the Vertical Blender/Dryer`s heated sidewalls is constantly being renewed.Coupled with vacuum conditions, this continuous turnover of the material leads to significantly shorter drying rates. Moreover, the blending action is gentle enough for even the most delicate of applications in which other agitated dryers (i.e. ribbon or paddle style blenders) may otherwise generate fines.

How a Vertical Blender/Dryer works:

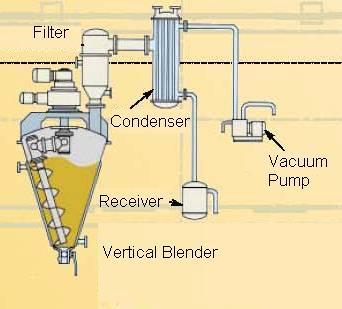

Heat is applied to the jacketed vessel of the vertical blender.Once vacuum is established, the combination of low absolute pressure, gentle heat and slow agitation quickly forces moisture from the bulk material. Vapors generated in the process pass through a filter and into a condenser. A receiver collects the condensed liquid for proper disposal or re-use, if applicable.

Benefits of Ross Vertical Blender/Dryers

- Fully top-supported screw agitator. Without a bottom support bearing to get in the way, dried materials are discharged quickly and completely. This design also allows the machine to be operated with very little maintenance.

- Many standard sizes. Standard models range from 1 to 500-cu.ft. Larger custom units can be built for higher volume drying requirements.

- Smaller footprint compared to other types of dryers.

- Wide range of suitable feed forms - from slurries, wet cakes and pastes, to granules, beads, pellets, prills and powders.

- Highly effective moisture removal. Ross Vertical Blender/Dryers are commonly used for drying materials to less than 0.10% moisture.

- Low energy consumption and fast drying rates.

- Customers can rely on Ross for customizations and auxiliary equipment, including pneumatically operated valves, lump breaker assembly, custom ports and manways, spray nozzles, sanitary construction, load cells, temperature control units, vacuum pumps and operator stations.