Tech Report

Recommended Mixing Equipment For Emulsion Adhesives

Application Summary

Water-based emulsion adhesives serve multi-purpose uses in packaging, construction, textile and other applications. They bond plastic, coated papers, wood, metal surfaces, ceramics, concrete, glass and other substrates. Typical chemistries are formulated with polyvinyl acetate (PVA), ethylene vinyl acetate (EVA), acrylics and styrene-butadiene (SB) latex.

The mixing technologies utilized in the production of emulsion adhesives vary from one formulation to another. Mixer selection is based on a number of factors but primarily viscosity profile and shear input.

Ross High Shear Mixers and Multi-Shaft Mixers

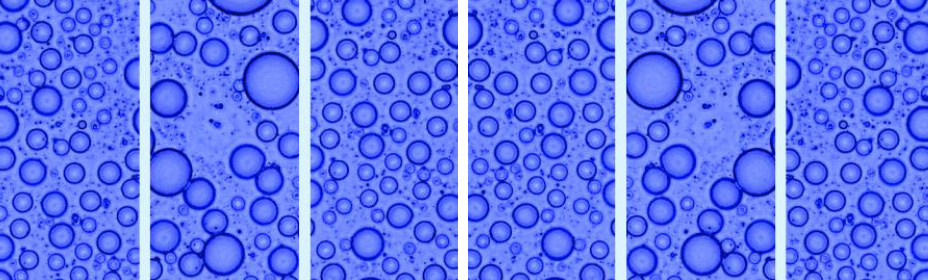

Adhesive manufacturers rely on a range of high speed mixers to accomplish emulsification. High Shear Mixers, for instance, are widely used throughout the industry for preparing aqueous emulsions under 10,000 centipoise (cP). The basic single-stage design features a four-blade rotor turning at tip speeds up to around 3,000-4,000 ft/min within a close tolerance fixed stator. It creates mechanical and hydraulic shear by continuously drawing product into the rotor and expelling it radially at high velocity through the openings in the stator. This type of mixer is available in both batch and inline (continuous) configurations.

Formulations that undergo viscosity changes peaking well over 10,000 cP are more efficiently batched in Multi-Shaft Mixers. These versatile machines are equipped with two or more independently-driven agitators working in tandem to deliver a combination of high shear agitation and laminar bulk flow. A Triple-Shaft Mixer featuring a low-speed anchor, rotor/stator assembly and saw-tooth disperser blade is particularly ideal for creating highly-filled emulsions. The agitators can be engaged in any combination and at any speed for any interval during the mixing cycle. Adjustable scrapers attached to the wings of the anchor agitator physically contact the vessel bottom and sidewalls. This allows for tighter temperature control in addition to enhanced product turnover. The saw-tooth disperser generates a vortex in the liquid surface for quick incorporation of solid ingredients and, along with the anchor, continues to agitate the batch when it becomes too thick to flow through the rotor/stator.

Ross Ultra-High Shear Mixers

More challenging emulsions generally require agitation at greater shear levels to achieve target physical characteristics. For example, when conventional rotor/stator devices fall short in producing the desired droplet size distribution in an adhesive emulsion, the next practical step is to utilize an Ultra-High Shear Mixer. Several designs are available including the Ross X-Series (US Patent No. 5,632,596), a unique inline rotor/stator engineered to run at tip speeds over 11,000 ft/min. It consists of concentric rows of intermeshing teeth; product enters at the center and moves outward through channels in the rotor/stator. The extremely close tolerance between adjacent surfaces of the rotor and stator is adjustable for fine-tuning shear levels and flow rates. With certain formulations, the X-Series Ultra-High Shear Mixer is proven to replace expensive colloid mills and high pressure homogenizers while producing a better quality emulsion at much higher throughputs and requiring simpler maintenance.