Tech Report

Recommended Mixing Equipment for Fumed and Precipitated Silica

Application Summary

High surface energy silicas require adequate shear for optimal dispersion into liquid. Improper powder wet-out and insufficient mixing lead to decreased efficiency (i.e. higher loadings of silica needed to achieve the desired properties), presence of large agglomerates, settling, poor stability and batch-to-batch inconsistencies. At the same time, operators must take care not to apply excessive agitation as this can result in unwanted temperature build-up and an irreversible loss of viscosity.

Ross High Shear Mixers with SLIM Technology

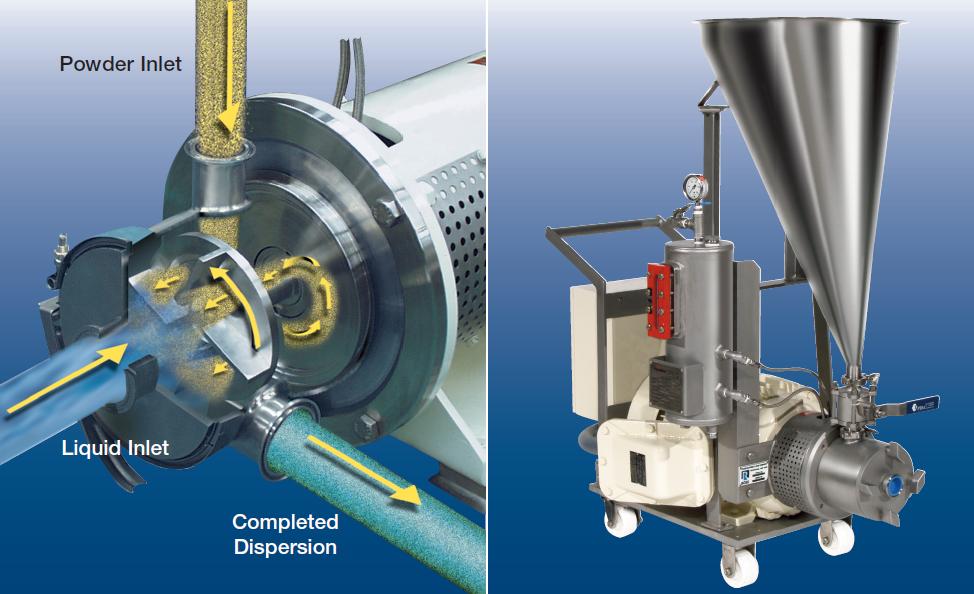

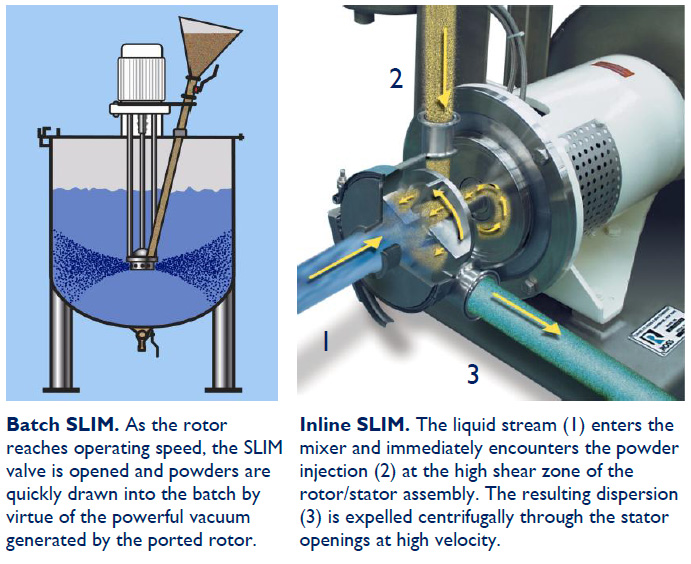

The Ross Solids/Liquid Injection Manifold (SLIM) Technology is proven to be extremely effective in wetting out and dispersing fumed silica and precipitated silica into liquid. The SLIM consists of a unique rotor/stator generator specially designed to create a powerful vacuum that draws and injects powders directly into the mixer`s high shear zone. Solids are thus wetted out at precisely the point where vigorous mixing takes place and dispersion is virtually instantaneous. Lumps and agglomerates that typically form upon contact with liquid are prevented from forming in the first place.

The SLIM technology is available in both batch and inline designs, making it simple to retrofit into existing processes. This system can disperse small concentrations of thickeners just as easily as it can handle solid loadings upwards of 70%, depending on the application, while operating within a wide viscosity range: from water-like to up to 10,000 cP during powder injection. After all the solids are added, product viscosity may continue to climb. For instance, batch SLIM rotor/stators are installed on Ross Multi-Shaft Mixers used for batching formulations with a final viscosity of several hundred thousand centipoise.

The Ross SLIM is proven technology for fast and efficient dispersion of different types of solids including:

- Alginates

- Alumina

- Bentonite Clay

- Boric Acid

- Calcium Carbonate

- Carbomers

- Carbon Black

- Carrageenan

- Cellulose Gum / CMC

- Citric Acid

- Dye Powders

- Guar

- Gum Arabic

- Hydroxyethyl Cellulose

- Magnesium Hydroxide

- Milk

- Pectin

- Starch

- Talc

- Titanium dioxide

- Whey

- Xanthan Gum

Processing advantages of the SLIM Technology

- Simple and straightforward operation. Just turn on the mixer and start inducting powders. No eductors or vacuum pumps to deal with.

- Cleaner and safer mixing. A "hose & wand" attachment is used for dipping into bulk bags or containers to conveniently induct lightweight powders like fumed silica without creating a dusty environment. Other solids can be loaded to a SLIM hopper at floor level. Operators no longer have to climb up mezzanines carrying bags of powder or manually add raw materials from the top of the batch tank.

- Shorter cycle times. The SLIM routinely cuts process times by 80% or more. In addition to curbing overall operating costs, a short mixing time also helps prevent over-shearing of silica dispersions.

- Increased yield and higher quality dispersions. Dispersing solids sub-surface using a SLIM mixer eliminates floating powders, agglomerates and "fish eyes". As yield and performance consistency are maximized from batch to batch, manufacturers benefit from substantial savings in raw materials costs and fewer reworks.