Tech Report

Specifying ribbon blenders

Technology Brief

This bulletin discusses some best practices and considerations for selecting and specifying batch ribbon blenders.

The multi-purpose ribbon blender

The classic ribbon blender is a familiar sight in production floors across the food & beverage, chemical, pharmaceutical, plastic, agricultural and other industries. Due to its versatility and economy, the ribbon blender is often the best choice for most mainstream blending applications.

Engineers tasked with procuring a new blender must recognize the different features and options that are available to optimize efficiency with respect to a specific application. Customizing the multi-purpose ribbon blender to meet your own process needs does not have to entail drastic costs. A simple but comprehensive review of key process details helps guarantee that your equipment is not underspecified or over-engineered.

Some blender selection and specification considerations

- The desired batch volume determines the size of the blender but product bulk density determines if a standard or heavy-duty model is required. Industry-wide, most standard ribbon blenders can typically handle bulk densities of around 35 lbs/cu.ft. More robust blenders are available for denser products. If you are producing different blends in one blender, factor in the lowest and highest densities to calculate the right blender capacity and motor size. Keep in mind that optimal mixing in a ribbon blender requires enough batch material - equivalent to at least 30-40% of the rated volumetric capacity.

- Material of construction on the wetted parts must be compatible with all raw materials that will be processed in the blender. This includes the trough, cover, agitator, discharge valve as well as the spray bar and safety grating, if any. Internal surfaces must be well-polished and each weld should be radiused to prevent material buildup.

- The most reliable drive design for a ribbon blender is a one-piece motor reducer or gearmotor. This direct drive arrangement is cleaner and more compact compared to antiquated chain and belt drives. It also reduces noise in the plant and eliminates maintenance headaches. Gearmotors are designed to work well with electronic inverters which provide enhanced speed control, overload protection and adjustable starting torques.

- The ribbon agitator can be supplied with an interchangeable paddle-style agitator which is recommended for gentler blending of fragile applications.

- To reduce dusting, use clamps to secure the gasketed cover and a dust-tight knife gate discharge valve (or a ball valve if you also need the blender to be liquid-tight).

- Install lantern rings on the packing gland when handling fine or abrasive powders. Maintaining a slight positive pressure of air during blending will prevent particles from penetrating the ribbon blender`s stuffing box and wearing the shaft.

- Testing is very useful in confirming blend quality and batch times. Ask your blender manufacturer about testing services or rental/trial programs. The latter is an excellent resource that allows you to put new ideas for process improvements to the ultimate test - in actual production.

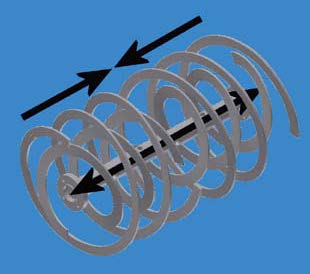

How ribbon blenders work

Ribbon blenders consist of a U-shaped horizontal trough and an agitator made up of inner and outer helical ribbons that are pitched to move material axially, in opposing directions, and also radially. This combination promotes fast and thorough blending. Tip speeds in the range of 300 feet/min are typical.

Sample Application: Dry Mix Beverages

An 18-cu.ft. Ross Sanitary Ribbon Blender installed at a beverage plant is being used to blend various dry mix recipes such as vanilla smoothies, hot chocolate, spiced apple cider, etc.

With their previous blender, cleaning between batches typically took 60 to 90 minutes. Operators literally attacked the blender`s corners with toothbrushes to remove all built-up material. With the Ross blender, cleaning time has been reduced to an average of 15 to 30 minutes. This has made a real difference in the company`s ability to change recipes quickly, squeeze another batch or two into an 8-hour shift and cut the risk of contamination to virtually zero.