Tech Report

Consider the advantages and disadvantages of scrapers

Technology Brief

The use of scrapers in batch mixing operations helps improve product homogeneity and heat transfer efficiency. However, there are cases wherein scrapers are not recommended such as in the processing of abrasive applications or highly viscous, sticky materials.

Role of scrapers in mixing

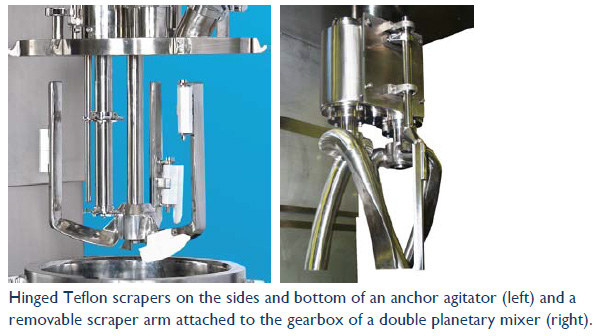

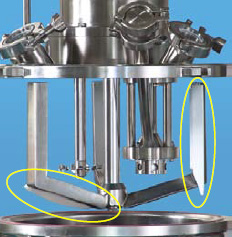

The presence of a scraping mechanism within a mixing vessel may be desirable for a number of reasons. To illustrate, consider the wide array of single-shaft mixing devices - from propellers and turbines, to saw-tooth dispersers and rotor/stators. All of these mixers face a common limitation: as batch viscosity rises, localized heating can occur in the areas surrounding the mixing blade as product flow starts to slow down. Meanwhile, materials close to the vessel walls become stagnant and do not benefit from the agitation in the tank.When this occurs, supplemental agitation near the periphery of the vessel becomes necessary. A second mixer, typically an anchor agitator, is used for moving product adjacent to the vessel surfaces. Its horizontal and vertical wings are designed to run at close proximity to the vessel. This in itself helps to constantly remove product away from the sidewalls and bottom providing more efficient turnover. The addition of scrapers, which actually contact the vessel surfaces, further improves product homogeneity and heat transfer efficiency.

Scraper material of construction

Teflon is a common material for scraper blades due to its low frictional property, non-reactivity and compatibility to a wide range of materials including medical - and food-grade products. For high-temperature mixing applications, alternate scraper materials may be chosen such as ultra-high molecular weight polyethylene (UHMWPE), Nylon and other plastics.

Possible issues with scrapers

In certain abrasive applications, particles can imbed in the scrapers and cause aggressive wear on the vessel surfaces being scraped. The agitator to which the scrapers are attached could also become exposed to unnecessary stress due to the excessive friction.Double planetary mixers, which are commonly used for handling viscous materials beyond the capacity of anchor agitators, can also be equipped with a scraper arm. This arm is affixed to the planetary gearbox and is often removable. For many viscous products made on planetary mixers, materials that temporarily stick to the walls during mixing are often reincorporated into the batch by the planetary stirring action without the need for additional scraping assistance. Quite commonly, when scrapers are used, material collected from the vessel wall builds up on the scraper arm and above the product level where it is not reincorporated back into the batch. This migration of batch material reduces mixing efficiency, necessitates intensive clean-up and can increase contamination risks. There are applications however wherein non-sticky products can benefit from scrapers to promote thorough mixing and maintain uniform temperature. Otherwise, not using scrapers is usually advantageous in a double planetary mixer.

Rule of thumb

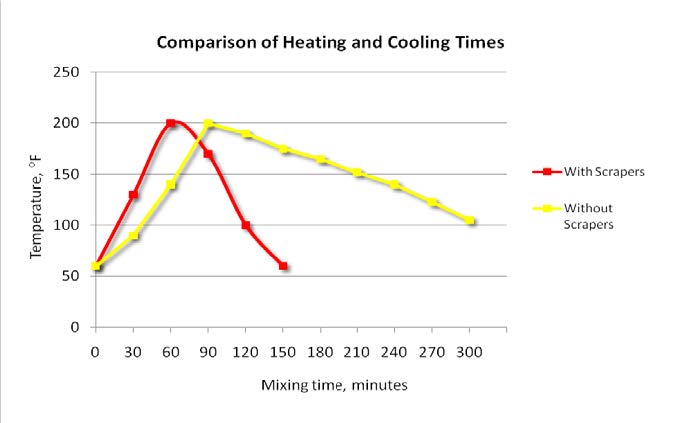

A good rule of thumb is to utilize scrapers for low to medium viscosity applications, especially when subsequent heating or cooling accompanies the mixing cycle. Viscous products made on planetary mixers must be tested to determine if mixing can be completed successfully without scrapers.

Scraper Installations onDifferent Style Mixers

Dual-Shaft Mixer

Triple-Shaft Mixer

Hybrid Planetary Mixer

Scrapers improve heating and cooling efficiencies.

The addition of wall and bottom scrapers is very important in mixing processes that require a fast response to temperature changes. The graph above shows that using scrapers reduced the heating time of a gel material by approximately 33%, while the cooling cycle was reduced by approximately 60%. The larger improvement in cooling time can be explained by the tendency of most products to increase in viscosity when cooled - materials near the jacketed sidewalls thicken up, and in the absence of scrapers, further inhibit product circulation and heat exchange.