Tech Report

Processing techniques for multi-agitator systems

Technology Brief

This bulletin discusses some processing techniques for mixing in a multi-agitator system.

Agitator combinations in multi-shaft mixers

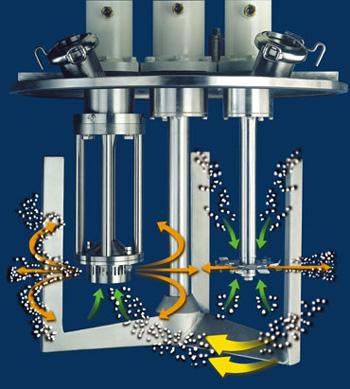

Multi-shaft mixers are comprised of two or more independently-driven agitators working in tandem. A low speed anchor compliments one or two high shear devices, such as a sawtooth disc-style disperser blade or a rotor/stator assembly. The disperser and rotor/stator are particularly effective at fast powder wet-out, dispersion and particle or droplet size reduction. However, both designs are inherently limited in terms of viscosity range.

On its own, a disperser blade will produce acceptable flow patterns for products around 50,000 centipoise (cP) maximum; the rotor/stator is even lower, around 10,000 cP. Hence, there is a need for a supplement agitator to improve bulk flow, deliver viscous product to the high shear devices and constantly remove batch material from the vessel walls for better heat transfer. The most common low speed agitator designs are the two-wing and three-wing anchors. For added efficiency, helical flights which help improve axial flow can be installed in between each wing.

In combination, a high speed disperser, rotor/stator mixer and anchor agitator will process formulations as high as a million centipoise depending on the product's shear-thinning tendency.

Some processing techniques

- Begin the batch with enough starting volume so that the disperser blade and/or rotor/stator are well-submerged and thus can work properly without "slinging" materials to the walls.

- Load low-melting point ingredients first. Manipulate the speeds of the anchor and disperser in order to wet out powders as quickly as possible.

- If the starting viscosity is fairly low (no more than 10,000 - 20,000 cP), you may benefit from a powder injection system that is available in some rotor/stator assemblies. Specially designed rotors can generate vacuum strong enough to draw powders right into the high shear zone within the stator. By introducing solid ingredients sublevel, floating, dusting and formation of agglomerates (fish eyes) are greatly reduced, if not eliminated completely.

- To achieve the best level of dispersion in a multi-shaft mixer, run the high speed disperser and rotor/stator mixer at full speed as soon as powders appear to be wetted out. Running at the maximum rpm is desirable as you benefit from the highest tip speed that the mixers can deliver. Well-designed mixers work just as optimally running at maximum speed as at lower speeds. Do look out for product splashing to the mixer cover and consider if your product is in any way heat- or shear-sensitive.

- Side and bottom scrapers on the anchor are often recommended as these can dramatically shorten heating and cooling times. The exception is when abrasive particles are present in the batch that could imbed in the scrapers and cause excessive friction on the vessel surfaces.

- Mixing under vacuum can provide many benefits including better dispersion, void-free finished product, and elimination of costly and timely downstream deaeration steps.

Multi-Shaft Mixer Sample Configurations

Sample Application: Contact Adhesives

A major manufacturer of solvent-based adhesives was using a bottom-entering high speed disperser to manufacture their line of construction adhesives. One nagging problem of this system was the recurrence of seal failures often accompanied by leakage of product out of the mixer, a serious concern due to the nature of the solvents being used (toluene, acetone, MEK, hexane and styrene). Another issue was the unacceptable amount of heat generated by the disperser. Running at its high-speed setting, the disperser blade would quickly bring the batch temperature above 100oF despite the running of cooling water through the jacket. As the polymers dissolved, an insulating layer coated the inner walls of the vessel, rendering the jacket ineffective. Because of this, the disperser was usually run at its low-speed setting, resulting in mixing times of over three hours.

By switching to a Ross VersaMix Triple-Shaft Mixer equipped with an anchor agitator, high speed disperser and rotor/stator assembly, the company cut their batch time to one hour. Mixing speeds are now easily controlled using variable frequency drives dedicated to each agitator. Batch temperature is also better managed through the use of scrapers attached to the anchor. Since the agitators in the VersaMix are all top-entering, the seal failure and leakage problems were permanently eliminated.