Tech Report

High-capacity rotor/stator mixers

Technology Brief

Inline rotor/stator mixers are ideal for large-volume high shear mixing requirements. Benefits include batch size flexibility, pumping capability and ease of installation.

High shear mixers: theory of operation

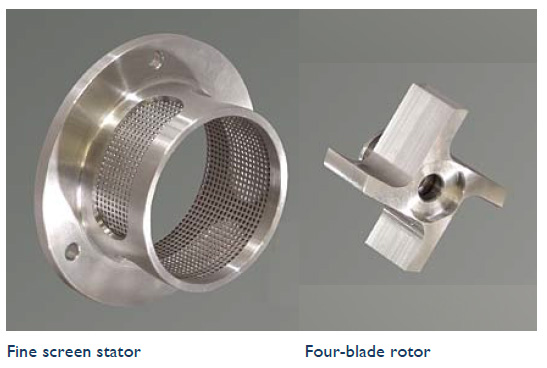

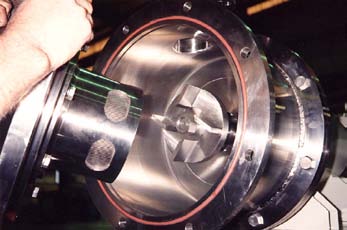

A rotor/stator mixer, also often called a high shear mixer, consists of a four-blade rotor turning at high tip speeds within a close tolerance stator, typically in the range of 3,000 to 4,000 ft/min. Product is subjected to high levels of hydraulic and mechanical shear before being expelled out of the mix chamber through the holes of the stationary stator. Ultra-high shear mixer designs with rotors that run up to 11,000 ft/min are also available.

Large-scale mixing, batch vs. inline

High shear mixers are available in both batch and inline (continuous) designs. In batch operations, the top-entering rotor/stator mixer is sized according to the tank volume or a range of operating volumes, if intended to be used on multiple vessels. For example, a 4" diameter rotor driven by a 10HP motor is normally used for low-viscosity batches (<20,000 cP) as small as 25 gallons and as large as 250 gallons. Within this approximate volume range and viscosity, the 10HP batch high shear mixer is able to produce adequate flow in the vessel. As batch volumes become larger, bigger rotors are required and it`s not uncommon to install an auxiliary propeller or anchor agitator to supplement bulk flow. Eventually, very large batch high shear mixers demand horsepowers that are impractical.

On the other hand, inline high shear mixers are sized according to flowrate, rather than tank volume. For instance, a 10HP mixer set up for recirculation can turn over 240 gallons of process fluid per minute (based on water-like viscosity). It can be used with virtually any size tank and cycle time is easily adjusted because the number of recirculations through the rotor/stator mixer is simple to predict. Unlike a batch mixer, which requires a high-horsepower motor to generate adequate circulation in a large vessel, an inline mixer can handle a 2,500-gal stirred tank as easily as it handles a 25-gal batch.

Other benefits of inline high shear mixers

An inline rotor/stator mixer behaves like a centrifugal pumping device. Typically positioned on the floor or on a platform below the liquid level, gravity usually feeds the product into the mix chamber. After the mixing cycle, the inline high shear mixer can pump the finished mixture to downstream equipment or storage vessels. Depending on the rotor/stator geometry, an inline mixer can handle viscosities up to 10,000-20,000 cP without external pumping assistance. With an auxiliary pump, it can process products up to 200,000 cP.

Another main advantage to an inline mixer is that it is easily installed without disturbing pre-existing equipment. Its configuration eliminates the difficulties of trying to squeeze a top-entering mixer into a vessel along with pre-existing agitators, baffles and other obstacles.

Anatomy of a RossInline High Shear Mixer

Four-blade rotor and interchangeable stators (slotted, round hole disintegrating and fine-screen).

Cartridge-type single mechanical seal.Double mechanical seals may be chosen for high-temperature or demanding applications.

Stainless steel 316 product contact parts, polished to 150-grit (32 Ra) finish. Sanitary 3A-approved models available.

Explosion-proof high efficiency motor.Stainless steel and/or washdown duty motors available.

Sample Application: Flocculants

Two Ross High Shear Mixers, Model HSM-4100, are in service at a chemical facility, each producing 3,000-gal batches of polyelectrolyte-based flocculants.

The mixing process involves bringing together a four-constituent aqueous phase with a three-constituent oil phase to produce the flocculant chemical. Raw materials are introduced to a 3,000-gal tank and recirculated through the HSM-4100 until complete. Batch time is 2.5 hours.

When the mix cycle is finished, the flocculant is again pumped through the rotor/stator on its way to a storage vessel. The finished product is shipped to industrial and municipal wastewater treatment facilities via bulk tankers and also in 55-gal drums.

The two HSM-4100 mixers have the following specifications:• 13" dia. four-blade rotor running at 1,200 rpm, driven by a 100HP motor.• Fine screen stator head.• Carpenter 20 rotor shaft to resist chloride attack.• Double mechanical seal with tungsten carbide/carbon faces.