Tech Report

How to increase shear without sacrificing throughput

Technology Brief

Ultra-high shear mixers are ideal for homogenization, emulsification and solubilization requirements where particle or droplet size is critical. These devices areas simple to operate as regular rotor/stator mixers but are capable of intense shear levels as well as high pumping rates.

High shear mixing

High shear rotor/stator mixers offer a popular strategy for homogenization, emulsification and solubilization. The conventional rotor/stator mixer generates its high shear characteristics through the interaction between a rotor with a peripheral tip speed in the range of 3,000 - 4,000 feet/minute and a fixed stator with a variety of available opening configurations. Process material is drawn into the mix chamber then expelled at high speed through the openings in the stator, thus subjected to mechanical and hydraulic shear.

Inline high shear mixers are utilized in single-pass, truly continuous operations but they are also commonly installed as part of a recirculation loop in a batch tank system. Particles or droplets suspended in the mixture are reduced in size with every pass through the rotor/stator assembly.

Need for greater shear

Depending on the formulation being mixed, multiple passes may be required to achieve the desired particle size distribution. This could significantly impact overall cycle time and operating costs, especially when recirculating a large batch. In addition, multiple passes through a rotor/stator mixer can indeed produce smaller particles or droplets but the improvement diminishes with each turnover until the size distribution reaches equilibrium.

If the equilibrium particle size achieved in a regular single-stage or multi-stage rotor/stator is larger than desired, manufacturers turn to more aggressive, higher energy devices such as colloid mills, media mills, three roll mills and high pressure homogenizers. Unfortunately, all of these options almost always entail a longer processing time due to their comparatively low throughput. The additional transfer steps, clean-up and maintenance also contribute to higher processing costs.

Ultra-high shear mixers: faster and cheaper alternative

The Ross X-Series, QuadSlot and MegaShear inline ultra-high shear mixers consist of special rotor/stator generators designed to operate at tip speeds over11,000 feet/minute. These machines offer a more cost-effective way of delivering very fine dispersions and emulsions.

The high tip speeds and complex, turbulent mixing patterns generated within theX-Series, QuadSlot and MegaShear rotor/stators enable them to impart extremely high levels of hydraulic and mechanical shear without sacrificing throughput.Particle size reduction down to submicron levels after a single pass has been proved in many applications. Even if recirculation is required, ultra-high shear mixers are capable of relatively high flow rates and are very easy to operate as well as maintain, therefore avoiding bottlenecks that would otherwise usually arise from the use of traditional milling equipment or high pressure homogenizers.

Ultra-high shear mixers are offered in laboratory (3" diameter rotor) and production sizes (up to 15" diameter rotor). Hygienic models designed to be cleaned and sanitized in place are available for processing sensitive applications.

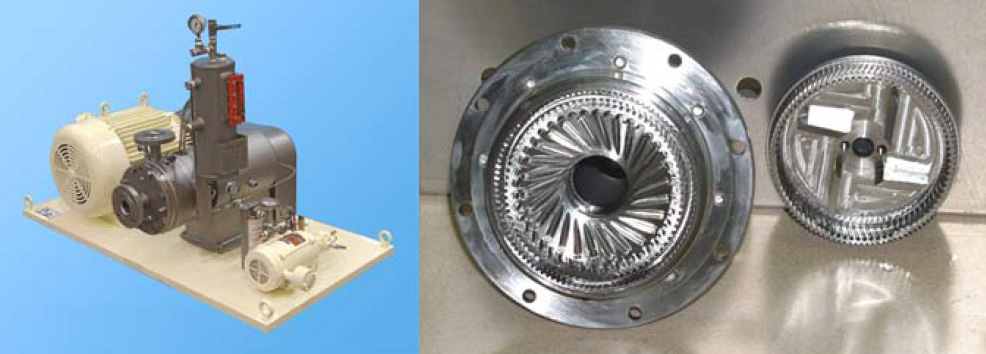

Ross Inline Ultra-High Shear Mixers

X-Series

The X-Series head consists of concentric rows of intermeshing teeth. Product enters at the center of the stator and moves outward through radial channels in the rotor/stator teeth. The combination of high tip speed and extremely close tolerances subjects the product to intense shear in every pass. The gap between adjacent surfaces of the rotor and stator is adjustable for fine-tuning shear levels and flow rates.

QuadSlot

The QuadSlot mixing head is a multi-stage rotor/stator with a fixed clearance. This generator produces higher pumping rates and requires higher horsepower compared to an X-Series rotor/stator set running at similar speeds.

MegaShear

The MegaShear operates at the same tip speed as the X-Series and QuadSlot heads, but is even more aggressive in terms of shear and throughput levels. It consists of parallel semi-cylindrical grooves in the rotor and stator towards which product is forced by high velocity pumping vanes. Different streams are induced within the grooves and collide at high frequency before exiting the mix chamber.

Sample Application: Polymer Slurries

Ross MegaShear Ultra-High Shear Mixers are used for preparing polymer slurries utilized in fluid hydrocarbon transportation.

Ground polymers are suspended into a liquid along with some additives then passed through theMegaShear. After sufficient mixing, the solid polymers become more finely divided in the slurry which helps them to be dissolved faster and work more effectively once added into solvents or pipeline fluids. These polymer slurries reduce the drag of a hydrocarbon flowing through a conduit, and hence decrease the energy requirement for transporting the fluid.