Tech Report

Recommended Mixing Equipment for Carbon Black Dispersions

Application Summary

Used in paints, inks, coatings, adhesives, sealants, plastics, electronics and specialty products, carbon black dispersions are typically prepared using high shear mixing or milling equipment to effectively break down agglomerates. As a reinforcing filler, pigment, conductive agent and UV stabilizer, carbon black must ideally be dispersed uniformly as primary particles to ensure optimal performance and full functionality.

In addition to shear intensity, operator safety is an important criterion in mixer selection. This is because carbon black has a very low bulk density and is usually supplied in the form of fine powders or pellets which tend to dust easily when scooped from the bag or poured into an open mixing vessel.

Ross High Shear Mixers with SLIM Technology

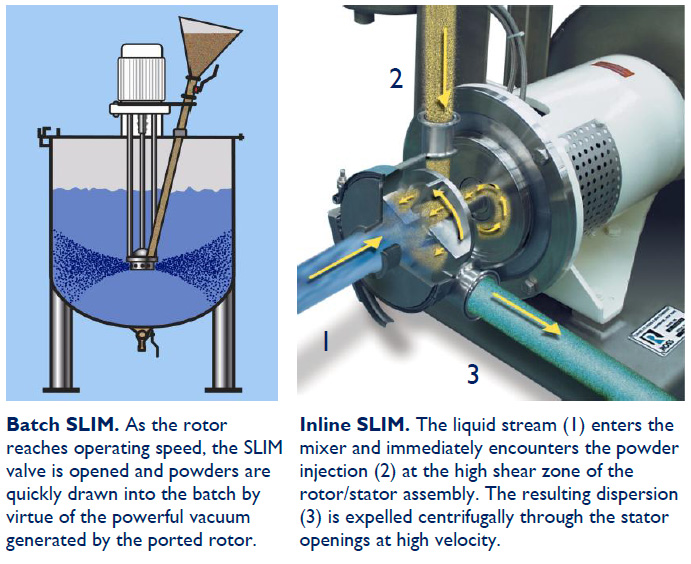

The Ross Solids/Liquid Injection Manifold (SLIM) Technology is proven to be extremely effective in dispersing carbon black powders into water or any low viscosity liquid. The SLIM consists of a unique rotor/stator generator specially designed to create a powerful vacuum that draws and injects powders directly into the mixer`s high shear zone. Dispersion is virtually instantaneous and production rates achieved in a SLIM mixer are significantly higher compared to traditional rotor/stator devices and milling equipment.

The SLIM technology is available in both batch and inline designs, making it simple to retrofit into existing processes. Unlike eductor-based powder injection systems, the SLIM routinely handles high solid loadings while operating within a wide viscosity range: from water-like to up to 10,000 cP during powder injection. After all the solids are added, product viscosity may continue to climb. For instance, batch SLIM rotor/stators are installed on Ross Multi-Shaft Mixers used for batching formulations with a final viscosity of several hundred thousand centipoise.

Ross also manufactures planetary-style mixers utilized for dispersing carbon black and other fillers into a highly viscous starting liquid.

Processing advantages of the Ross SLIM Technology

- Simple and straightforward operation. Just turn on the mixer and start inducting powders. No eductors or vacuum pumps to deal with.

- Easier material handling. The inline SLIM mixer is usually installed at floor level so operators no longer have to climb up mezzanines carrying heavy bags of powder. It is also portable and can easily serve multiple tanks.

- Safer mixing. A "hose & wand" attachment is used for dipping into bulk bags or containers to conveniently induct lightweight powders without creating a dusty environment.

- Higher quality dispersions. By eliminating floating powders and stubborn agglomerates, the SLIM maximizes both yield and functionality of carbon black and other solid raw materials. Shorter cycle times. SLIM users experience a significant reduction in overall mixing time, often by as much as 80% or more.

- Convenient maintenance. Compared to most milling equipment, a SLIM mixer does not require intensive clean-up and is much easier to maintain.