Tech Report

Recommended Mixing Equipment for Milk Powders

Application Summary

Dissolving powders like milk, whey, cocoa, sugar, thickeners and stabilizers into liquid can be a processing challenge. Conventional batch mixing systems commonly suffer from long cycle times, floating powders, lump formation and excessive foaming. One proven solution is to introduce the dry ingredients via sub-surface injection under high shear conditions. Technologies like the Ross Solids/Liquid Injection Manifold (SLIM) offer dairy manufacturers a faster and more practical method of powder dispersion which also helps prevent lumping and foaming.

Ross SLIM Technology

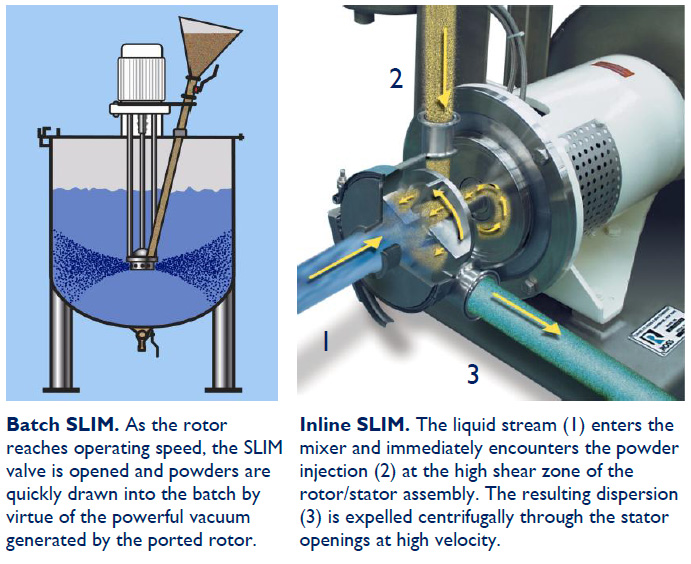

The Ross Solids/Liquid Injection Manifold (SLIM) Technology is well proven for fast and complete dispersion of milk powders into water, cream or other liquid base. The SLIM is a unique rotor/stator mixer designed to create a powerful vacuum that draws powders sub-surface and injects them into a high shear mixing zone.

In conventional batch mixing systems, milk powders are added into the vortex of an agitated liquid. Prolonged mixing at low speeds is sometimes necessary to due to persistent lumping and excessive foaming. By comparison, the SLIM enables rapid addition of milk powders and even hard-to-disperse solids, like gums and thickeners, without subsequent lumping. Mixing is more efficient in a SLIM process because solids and liquids are combined sub-surface at precisely the point where intense agitation takes place. The formation of lumps and "fish eyes" is greatly reduced, if not eliminated. Dispersion is virtually instantaneous.

The SLIM technology is available in both batch and inline designs, making it simple to retrofit into most existing processes. During powder injection, liquid viscosity could be water-like or as high as 10,000 cP. After all the solids are added, product viscosity may continue to climb. For instance, a batch-style SLIM rotor/stator installed on a Ross Multi-Shaft Mixer can be used for batching formulations with a final viscosity of several hundred thousand centipoise.

The Ross SLIM is proven technology for fast and efficient dispersion of many other solids including:

- Alginates

- Alumina

- Bentonite Clay

- Boric Acid

- Calcium Carbonate

- Carbomers

- Carbon Black

- Carrageenan

- Citric Acid

- Dye Powders

- Ground Rubber

- Guar

- Gum Arabic

- Hydroxyethyl Cellulose

- Magnesium Hydroxide

- Pectin

- Starch

- Sugar

- Talc

- Titanium dioxide

- Whey

- Xanthan Gum

Processing advantages of the SLIM Technology

- Simple and straightforward operation. Just turn on the mixer and start inducting powders. No eductors or vacuum pumps to deal with.

- Shorter cycle times. SLIM users report significant reductions in their overall mixing time, often by as much as 80% or more.

- Increased yield and higher quality dispersions. By preventing the formation agglomerates and eliminating floating powders, the SLIM maximizes both yield and functionality of solid raw materials.

- Easier material handling. The inline SLIM mixer is usually installed at floor level so operators no longer have to climb up mezzanines carrying heavy bags of powder. Solids can also be delivered via automatic feeding devices.

- Cleaner and safer mixing. A "hose & wand" attachment is used for dipping into bulk bags or containers to conveniently induct lightweight powders without creating a dusty environment.

- Flexibility. The 3A-approved Inline SLIM can be supplied on a mobile cart to serve virtually any size vessel located anywhere in the plant.