Tech Report

Reduce foaming and air entrapment during mixing

Technology Brief

Foaming and air entrapment are common phenomena encountered in many mixing processes. Different applications call for different solutions, including addition of chemical defoamers, mixing under vacuum and high-speed sub-surface powder induction.

Foaming and air entrapment

Foaming is a very common mixing issue. In many applications, it is an unavoidable side-effect of mixing, shearing and powder incorporation. The higher the agitator or blade speed, the better the mixing but also the greater the amount of foam created and the more the air entrained within the batch. The presence of surfactants can cause or exacerbate foaming but they often play a number of essential functions in the formulation and so are typically indispensable.

However, just because foaming is expected to occur does not mean it cannot be managed or at least minimized. Excessive foam formation can interfere with the mixing operation by artificially raising batch volume, causing prolonged cycle time, difficult handling, reduced productivity, product loss and extensive clean-up. Entrapped air that remains in the finished mixture can cause structural problems, clouding, discoloration, voids, instability and other undesired qualities depending on the product and end use.

Chemical defoamers

Chemical defoamers are additives that serve to prevent and destroy foam. Different applications require different levels and types or combinations of defoamers. The main disadvantages to using anti-foam agents are their high cost and, in some products, they are considered to be contaminants.

One way to reduce dependence on chemical defoamers is to apply certain modifications to the mixing operation. Below are three strategies for managing foam and air entrapment.

Some useful techniques

- When using a top-entering agitator to add powders into a foamy liquid, position the mixer blade off-center to decrease the vortex. Reducing the size of the vortex will minimize foaming and reduce the amount of air incorporated into the batch.

- Many operators try to reduce air entrapment by reducing agitator speed. But often this technique is counter-productive because it also reduces the rate of batch turnover and the level of shear provided by the agitator, which may be necessary to complete a good quality batch within a reasonable amount of time. Processing under vacuum is a better solution. Vacuum mixing allows full-speed agitator operation without entraining air. Always visually monitor the contents of the vessel as vacuum is applied. Use a sight glass to watch for changes in volume. Once an agitation phase is completed, reintroduce air into the chamber headspace gradually.

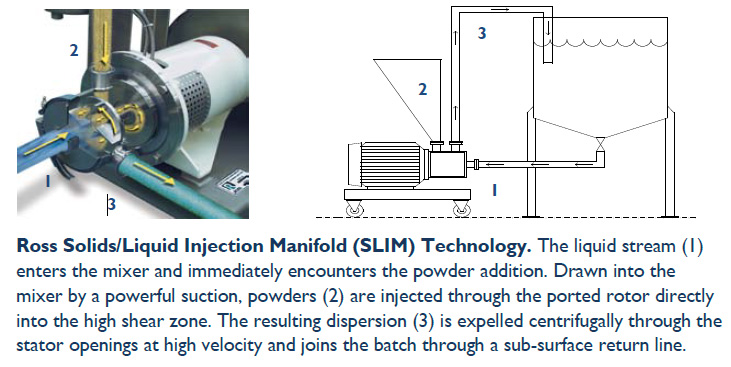

- If practical, replace or supplement a top-entering agitator with an inline mixer piped for recirculation. The return line must extend below the liquid surface to help prevent foam generation. For recipes involving large amounts of solids, choose an inline rotor/stator mixer equipped for high speed powder dispersion.

Installation Snapshot

At this cosmetics manufacturing plant, a high-speed powder induction system is used to solubilize and disperse ingredient additions - from various gums to aloe vera, oils and surfactants.

By supplementing their traditional turbine agitator with an inline Ross SLIM mixer, the company doubled their production capacity and improved product quality. Compared to the previous process where ingredients were simply dumped on top of the agitated liquid, the new mixing method completes each batch withless foaming and dusting.