In the News

Precise High-Speed Dispersion and Agitation with the ROSS CDA-200 Dual Shaft Mixer

Experts Corner

Navigating Supply Chain Disruptions in 2026: Why U.S.-Built Mixing Equipment Matters

Rossby the numbers

0+years of innovation

Since the company was founded in 1842, we have built a reputation for innovative engineering, superb construction and fast delivery.

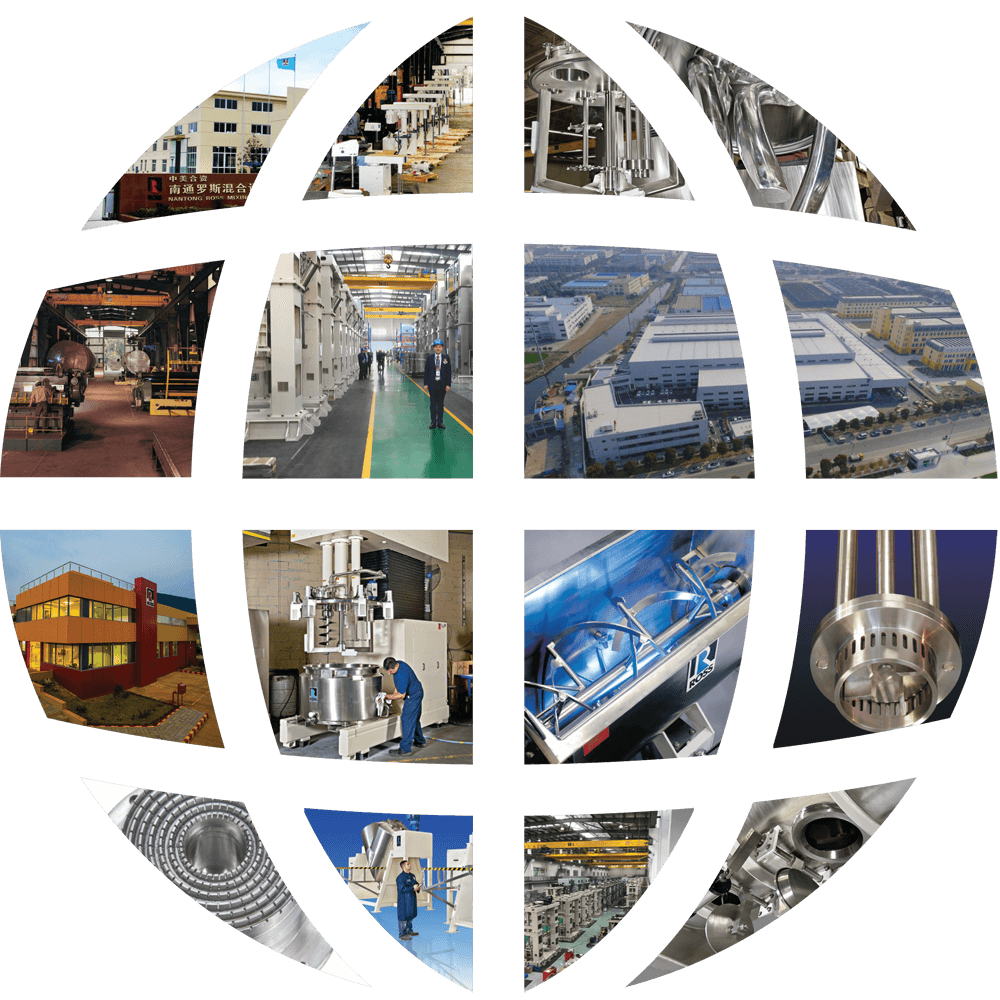

0worldwide manufacturing facilities

With manufacturing and sales offices located worldwide, ROSS can support your mixing and blending needs globally.

0growing product lines

Our mixing, blending, drying and dispersion equipment, is available in either standard or custom designs, to meet your specific processing needs.

0+employees

The ROSS family has owned the company since its inception. In 1999, the company established an ESOP for its employees. All of the company's employees now share in the ownership.

Real World Solutions

Building a Better Industrial Mixer

ROSS has manufactured industrial mixing, blending, drying and dispersion equipment since 1842. Standard and custom designs are available to meet the varied processing requirements of our customers. We design and build our mixers and blenders in company owned plants in the United States, China and India. All of our plants are all fully equipped with advanced engineering and manufacturing tools. In the USA alone, we operate five plants and maintain an 8000 sq. ft. Test & Development Center.

Our mixers and blenders are used throughout the process industries for the production of food & beverage, pharmaceuticals, adhesives & sealants, battery slurries, electronic pastes, ceramics, metal blends, inks, coatings, cosmetics & personal care products, plastics, composites, specialty chemicals and many other applications.

Video Resources

Video Library

ROSS Mixers for Battery Manufacturers

Engineering Experts

Resources containing in-depth mixing knowledge, advice, and solutions.

Recommended Blending Equipment for Pet Food

One critical step in pet food production is the preparation of intermediates wherein powders, ground solids and other dry ingredients are blended together, sometimes along with minor liquid components.

Ultra-high shear mixers increase overall throughput and efficiency of homogenization processes

Ultra-high shear rotor/stator systems speed up cycle time by reducing the number of passes required through a high pressure homogenizer, an inherently low-throughput, high-energy device. Since homogenizers are also generally maintenance-intensive, an efficient ‘pre-mixer’ generates significant savings in the overall cost of production. In certain applications, ultra-high shear mixers even effectively replace homogenizers..

Recommended Mixing Equipment For Emulsion Adhesives

Water-based emulsion adhesives serve multi-purpose uses in packaging, construction, textile and other applications. They bond plastic, coated papers, wood, metal surfaces, ceramics, concrete, glass and other substrates. Typical chemistries are formulated with polyvinyl acetate (PVA), ethylene vinyl acetate (EVA), acrylics and styrene-butadiene (SB) latex. The mixing technologies utilized in the production of emulsion adhesives vary from one formulation to another. Mixer selection is based on a number of factors but primarily viscosity profile and shear input.

High Speed Mixing: Saw-tooth Dispersers vs. Rotor/stator Mixers

The saw-tooth disperser and rotor/stator mixer are two of the most widely used high speed mixers yet many are unaware of the differences in their utility and operating capacities. Knowing the unique attributes of these devices is important in mixer selection and process optimization.

High Shear Mixing and Single-Pass Emulsification

Consider an ultra-high shear mixer for your single-pass emulsification requirements. Advantages include simple operation, high throughput rates, consistent product quality, easy cleaning procedure and low maintenance.

Tips for selecting the best planetary mixer for your process

This bulletin presents some general guidelines for selecting the most appropriate planetary mixer configuration for a particular application.

Reduce cycle time in your large capacity mixer.

This bulletin discusses a method of raw material handling and addition that simplifies large capacity mixing and can reduce cycle times by up to 80%.

Benefits of tumble blending in the food industry

Tumble blenders deliver highly accurate and repeatable mixing of solid-solid and solid-liquid applications. This bulletin presents some helpful techniques and design considerations for maximizing blending efficiency.

Automation

A leading supplier of control systems for speciality processes

ROSS SysCon is a leading supplier of control systems for center stage processes including mixing, blending, dispersion, & drying, as well as accompanying processes including but not limited to charging, discharging, & CIP. Our products range from simple on/off switches to complete automation and PLC based recipe systems. Each system, standard or custom, is UL certified and designed and programmed in house according to the needs of each client.