Tech Report

Continuous static mixing of multiple process streams

Technology Brief

In many processes, mixing in pipelines is simpler and more economical than in vessels. In particular, continuous large-scale mixing of multiple liquid streams is easily accomplished in a static mixer arrangement. Advantages include fast blending, low maintenance, easy installation, and low energy requirement.

Advantages of static mixing

Static mixing offers several advantages over motorized mixer systems. For one, the only energy requirement in static mixing is the external pumping power necessary to move the product and compensate for pressure drop through the mixer. Residence times are typically short in a static mixer, making it ideal for fast blending requirements. This type of mixer is also commonly used to meet industrial requirements for absorption, reaction, extraction, and heat transfer/phase change.

Static mixers are installed as easily as a typical segment of pipe. Maintenance and space requirements are minimal. Well-designed static mixers offer predictable performance and can handle gas-liquid, liquid-liquid and solid-liquid mixtures over a broad range of flow conditions.

Static mixers

A static mixer is a unique device in that it has no moving parts and it relies on external pumps to move fluids through it. An array of static mixer elements is placed inside a pipe and the conduits, plates or baffles within the device manipulate the fluids to divide, recombine, spread, rotate, eddy or swirl.

Process factors considered in static mixer design selection include allowable pressure drop, heating/cooling requirements, length of piping, flow rates, viscosities, densities, etc.

Continuous mixing in pipelines

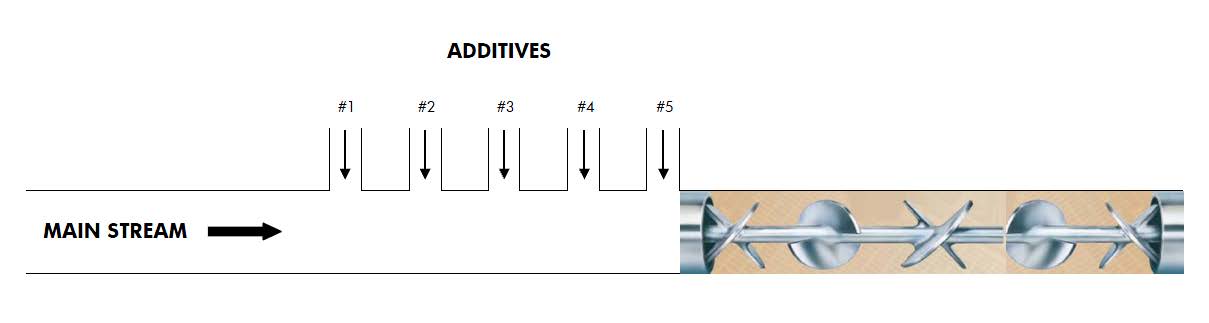

In many cases, mixing in pipelines is better and more economical than in vessels. In particular, continuous large-scale mixing of multiple process streams is easily accomplished in a static mixer arrangement. The diameter and number of elements in an assembly depend on the degree of mixing required. Generally, the diameter of the mixer is the same size as the process pipeline. Proper dosing of the feed components is controlled through metering pumps. Engineers use accurate correlations for predicting pressure drop within a specific static mixer design given the diameter, length, and other process parameters.

Sample Application: Fuel Blending

In the manufacture of gasoline for automotive use, refineries blend in a series of streams consisting of various additives, color components and chemical compounds that enhance fuel performance. Typically, this blending operation is the final step before the gasoline leaves the refinery, thus it is important that great uniformity is accomplished.

In the past it has been assumed that turbulence induced by pumping the material across a distance equivalent to 100 pipe diameters is sufficient to produce a good mixture. More current studies however show that some materials, due to differences in density and/or viscosity, do not actually blend into the main stream but ride along the bottom or top of the pipe en route to the tank farm. In several refineries, Ross LPD (Low Pressure Drop) static mixers ensure complete mixing of all additives and gasoline in an extremely short run of pipe.