Tech Report

Streamline your mixing process

Technology Brief

Installing an inline powder injection system with large batch tanks can significantly reduce cycle times, simplify clean-up and maintenance, enhance batch-to-batch consistency and improve overall production efficiency.

Large-scale batch mixing

Many mixing operations batching 500 gallons of product or more at a time require multiple "pre-mixing" steps to combine two or more raw materials before adding them into the main batch tank. Because these vessels are often equipped with slow speed agitators such as turbines, propellers or anchors, certain raw materials need to be mixed into a smaller volume of liquid in order to create a good dispersion, prevent agglomerates (fish eyes) and eliminate dusting.

This method however can be very labor intensive and time-consuming depending on the mixing application. Workers need to operate multiple mixers, transfer intermediates from one vessel to another, and clean up several containers. Improving this part of the mixing operation will not only cut overall cycle time and simplify material handling but also enhance batch-to-batch consistency.

Powder injection technology

One way of streamlining a large batch mixing operation is to utilize an inline powder injection system such as the Ross Solids/Liquid Injection Manifold (SLIM). This external mixer is piped to the main tank like a pump in a recirculation loop. Instead of being charged on top of the batch (where they can float or take too long to completely wet out) or pre-combined with other ingredients in smaller side tanks, solids are quickly injected into the recirculating liquid stream. The SLIM utilizes a unique rotor/stator set designed to generate a powerful vacuum for drawing powders directly into the high shear zone within the mix chamber, where they can be instantly dispersed into the liquid stream. Solids and liquids are combined at the point where flow is most turbulent so agglomerates are prevented from forming. The occurrence of floating powders is also eliminated.

For added convenience, a hose & wand device may be attached to the powder inlet of the SLIM to allow the operator to simply draw powders straight from within their original bulk container. This powder handling method is recommended for lightweight and fluffy powders as it generates virtually no dusting and is very operator-friendly.

Installation scenarios

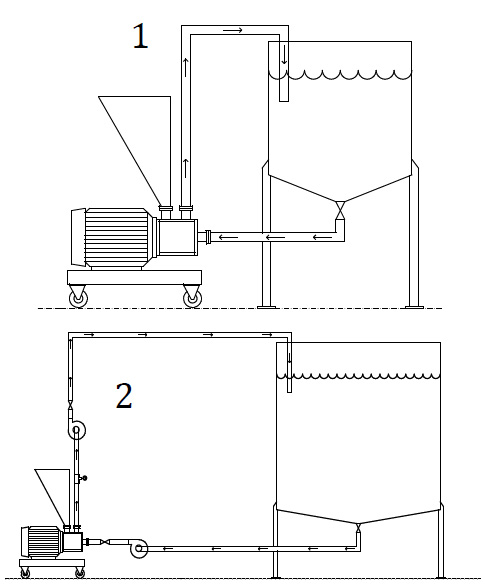

Scenario #1 describes the inline SLIM system being used with a nearby recirculation vessel (50 -1000 gallons).The mixer is located on ground level and is as close to the outlet of the tank as possible. Discharge tubing is kept to the minimum possible length.

Scenario #4 describes the inline SLIM being used with a very large recirculation vessel located at a considerable distance.Two pumps are used to feed the mixer and to minimize back pressure.

How the SLIM technology works

The above illustration shows how an inline SLIM mixer works. The liquid stream (1) enters the mixer and immediately encounters the powder addition. Drawn into the mixer by a powerful vacuum, the powder (2) is injected through the ported rotor directly into the high shear zone. The resulting dispersion (3) is expelled centrifugally through the stator openings at high velocity.

Sample Application: Specialty Cosmetics

A cosmetic manufacturer was looking to optimize cycle time in their two 500-gallon and two 1000-gallon vessels, each equipped with turbine impellers for turning over the batch. One particular bottleneck was the mixing of calcium stearate powders into glycerin in separate 55-gallon drums using a sawtooth disperser. After mixing, an operator had to lift the drums on top of the mezzanine and manually charge the calcium stearate dispersion into the batch.

Testing done on a 25HP inline SLIM confirmed that a single portable unit can serve all four main tanks and disperse calcium stearate directly into each batch.By eliminating the drum mixing step, the company was able to drastically reduce mixing and cleaning time from hours to minutes.